At Tankline, quality isn’t just about the materials we use — it’s about how we verify, document, and prove the performance of every lining system we apply. Whether we’re installing epoxy coatings in a steel tank or laminating GRP in a bund, test equipment plays a vital role in ensuring long-term success.

Here’s a look at the key instruments we use and why they matter.

Elcometer 224 – Surface Profile Gauge

Before any coating is applied, we grit blast the substrate to achieve a clean, textured surface that allows for proper adhesion. But not all blast profiles are equal.

The Elcometer 224 allows us to:

- Measure peak-to-valley depth in microns

- Confirm the profile meets the coating manufacturer’s specification

- Record consistent, traceable results for QA documentation

✅ A good blast profile is the foundation of a successful lining system.

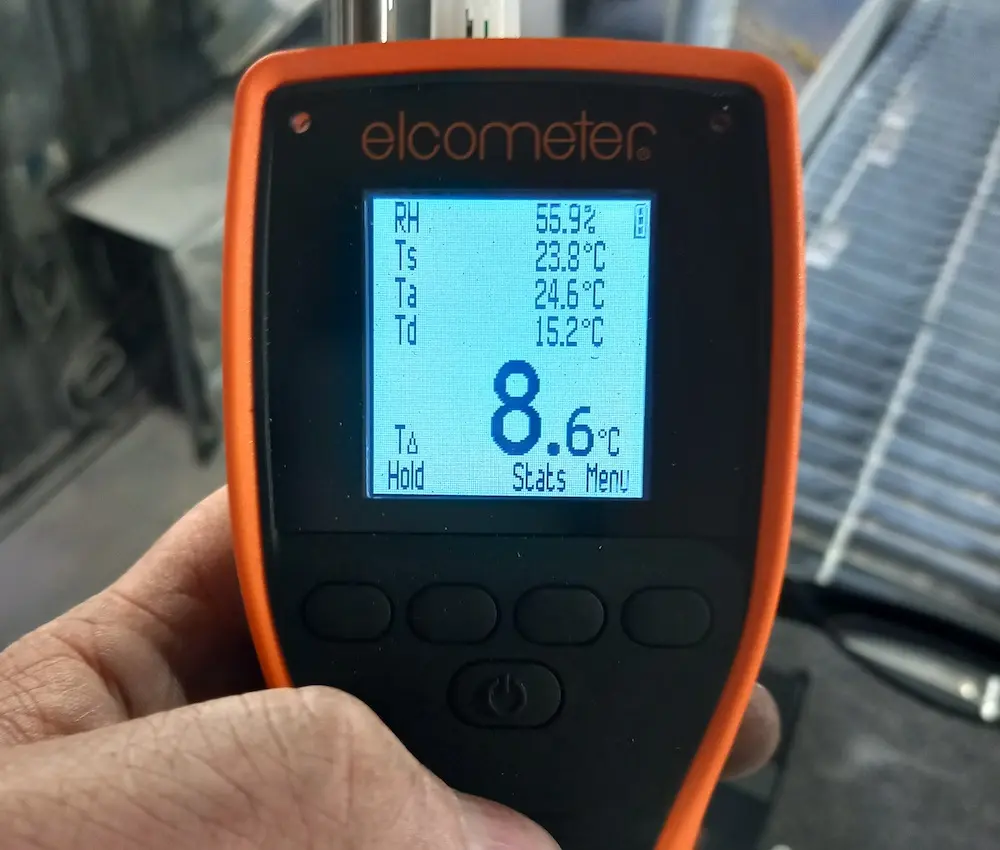

Elcometer 319 – Climate Monitoring Gauge

Temperature and humidity can significantly affect how a coating cures. Too damp or too cold, and you risk failure.

We use the Elcometer 319 to monitor:

- Air temperature

- Relative humidity

- Dew point

- Substrate temperature

✅ This ensures we’re always applying linings within the correct climatic window, reducing the risk of blistering, pinholing, or poor adhesion.

Wet Film Thickness (WFT) Gauges

When applying high-build linings like 100% solids epoxy, it’s critical to apply the correct thickness on the first pass.

Our applicators use wet film combs to:

- Check the coating is being applied at the specified WFT

- Make adjustments in real-time during spraying

- Ensure minimum dry film thickness (DFT) will be achieved after curing

✅ Getting it right during application saves time, avoids rework, and ensures long-term protection.

Elcometer 456 – Dry Film Thickness (DFT) Gauge

Once the coating has cured, we use the Elcometer 456 to take non-destructive DFT readings. This confirms that the correct amount of product has been applied across all areas, including edges and welds.

✅ All readings are logged, photographed, and included in our quality control report for full transparency.

Holiday Tester – Porosity Detection

Even a perfect-looking finish can hide pinholes, voids, or holidays (missed spots). We use a holiday tester to identify areas where the lining may be compromised.

The tool passes a high-voltage charge over the surface — if it finds a defect, it arcs, and we mark it for repair.

✅ This final test ensures your asset has a continuous, defect-free barrier against corrosion and chemical attack.

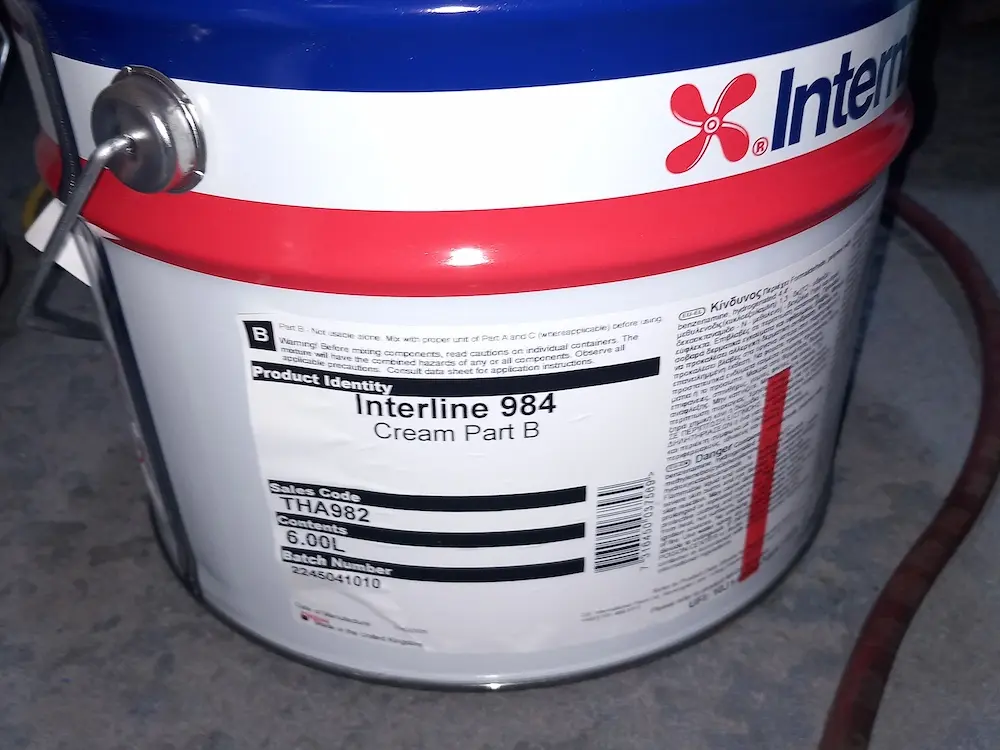

Paint Batch Numbers – Full Traceability

Every drum or tin of coating product we use comes with a unique batch number from the manufacturer. At Tankline, we record these for every coat applied, ensuring full traceability from the surface prep stage to final cure.

Batch numbers are logged in our quality control sheet, alongside:

- Product name

- Manufacturer

- Date and time of mixing

- Applicator initials

✅ Why it matters:

Recording batch numbers means that if a failure ever occurs (e.g. due to off-spec material or supplier defect), we can trace it directly to the source. It also proves that all materials were in-date, manufacturer-approved, and applied under the correct conditions

Final Thoughts

Anyone can spray a coating. But at Tankline, we prove our work holds up to the harshest conditions. Our trained technicians use calibrated test equipment, follow manufacturer specifications, and provide full QA documentation on every job.

Because in our world, performance is measured — and we’ve got the data to back it up.

Need a lining system that’s built — and tested — to last?

Get in touch with Tankline today on 01206 670309 or visit www.tankline.co.uk